Quality

Our Commitment

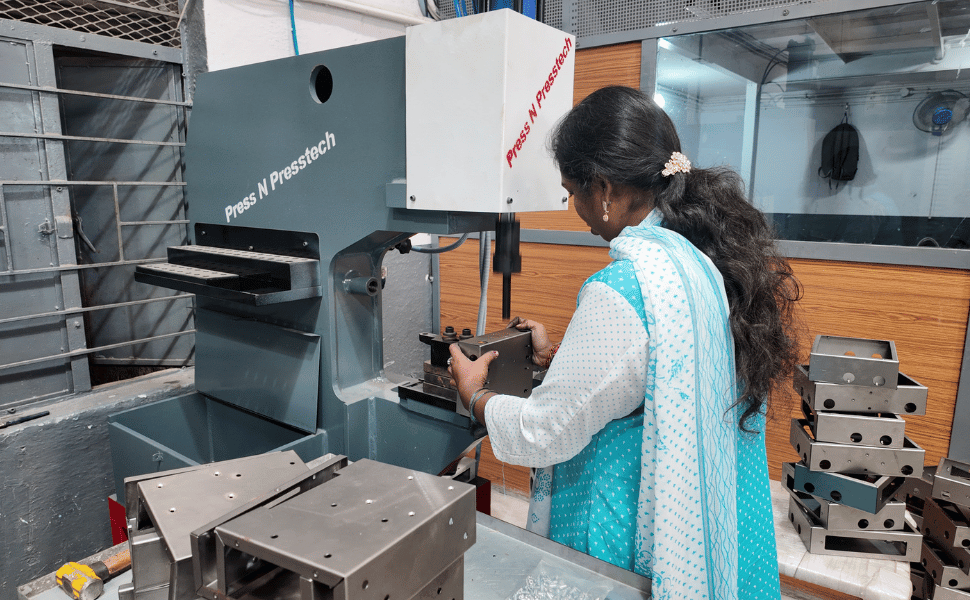

At Unique Lasers Fabricators, we are committed to delivering excellence in every project we undertake. Our focus is on providing precision-engineered sheet metal products that meet the highest standards of quality, durability, and performance. With advanced infrastructure, skilled professionals, and strict quality checks, we ensure that every product reflects our promise of reliability. More than just fabrication, our commitment is about building trust, delivering on time, and creating value for our customers at every step.

Let’s build precision together – your ideas, our fabrication

Reach out to Unique Lasers Fabricators today for reliable sheet metal solutions

Quality Control Process

At Unique Lasers Fabricators, we believe that quality is not just an outcome but a continuous process. Every stage of production, from raw material procurement to final delivery, is monitored through strict quality control practices. Our skilled team ensures that each product undergoes detailed checks for accuracy, durability, and finish. With advanced CNC machines, measuring equipment, and inspection protocols, we guarantee that every enclosure, machine body, or custom product leaving our facility meets international standards and exceeds customer expectations.

Key Steps in Our Quality Control Process:

-

Material Inspection – Careful selection and verification of raw materials for consistency and strength.

-

Precision Cutting – CNC laser cutting with dimensional accuracy and burr-free edges.

-

Bending & Shaping Checks – Ensuring correct angles, dimensions, and uniformity in all bends.

-

Welding & Riveting Quality – Strong, clean joints verified for durability and stability.

-

Final Inspection – Comprehensive checks for measurements, finish, and overall product quality.

-

Customer Assurance – Delivering only products that meet our strict quality standards.

Quality Policy

Quality system

Our team conducts regular audits, in-process checks, and final inspections to maintain consistency, accuracy, and durability. By integrating technology, skilled expertise, and documented procedures, our quality system not only guarantees reliable products but also supports continuous improvement and customer satisfaction.

Inspection Methods

Our inspection process begins with raw material checks and continues through each stage of fabrication—cutting, bending, welding, riveting, and finishing. Using advanced measuring instruments and strict monitoring practices, we verify accuracy, strength, and durability before final delivery. This structured approach allows us to maintain consistency, reduce errors, and guarantee reliable products for our customers.